- Alubond Stainless Steel

- Features

- Technical data

- Advantages

ALUBOND SOLID

Alubond U.S.A SOLID is the latest offering in high performance solid aluminum panel technology set to cater to the designer requirements of modern architectural façades. Alubond U.S.A SOLID is a Class A1 Non Combustible material and hence suitable in all Fire Rated Applications. Alubond’s unique continuous coil coating process and choice of high strength alloys like 3003 and 5005 series has given a new performance dimension to the use of solid aluminum in Architectural Façades and Solid Metal Applications.

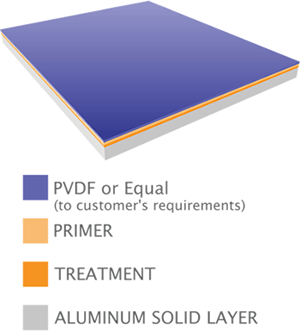

With a wide range of selection in PVDF coatings and Innovative Thermal Reflective Solar Cool Coatings, Alubond U.S.A SOLID offers aluminum panels of thickness 2mm & 3mm with the following attributes:

– Economical as compared to previous coated solid aluminum panels

– Perfectly flat façade panel

– Available in 3000 & 5000 alloy series

– PVDF/PUPA/Solar Cool Coating applied in 2, 3 or 4 coats

– In line with Alubond U.S.A world class quality standards

– 100% Recyclable and qualifies for LEED certified green buildings.

Advantages

LIGHT WEIGHT: yet extremely rigid and flat resulting in an economical option for high quality building façades and interior cladding.

WEATHER RESISTANCE: Combined with high Acoustics and thermal values

NON COMBUSTIBLE: High fire rating value, Class A1

EXTENSIVE CHOICE: of finishes including Metallic, Granite & Veneer

HIGHLY MALLEABLE: High product flexibility, The panel can be fabricated into complex shapes and designs allowing the panel to have versatile applications.

100% RECYCLABLE: Giving the building a high post usage value

ALUBOND U.S.A SOLID GREEN: Made using 75% Post Consumer Recycled content.

Applications

Alubond U.S.A SOLID’s array of colors and finishes combined with the inherent capability of forming different shapes and contours with durability and weather resistance makes Alubond U.S.A SOLID an Architect’s Dream! Major Corporations and Multinational Companies have a definitive desire to make their structures an expression of a Personal Designer Statement. Alubond U.S.A becomes a natural choice to achieve this objective. The possible applications are limited only to the Architect’s imagination…

Common applications of Alubond U.S.A SOLID are:

– Circular Columns

– Building Façades

– Wall Paneling Concepts

– Soffits and Beams

– Metal Ceilings and Partitions.

ALUBOND A2 - Features

Alubond A1 – Creating A Sustainable Future

Alubond U.S.A is a metal composite panel consisting of two layers of a metallic skin like Aluminum, Stainless Steel, Copper, Zinc, Titanium etc., sandwiching a fire rated core in a continuous co-extrusion process.

Alubond U.S.A is a registered brand of American Building Technologies located in Rockford Illinois with production bases in Europe, Middle East and India. Alubond U.S.A is committed to a sustainable future and is now available in three fire rated cores and an innovative eco friendly green core.

Alubond U.S.A has emerged as The World’s Largest ACP Brand with new expansions under progress in Russia, Saudi Arabia and Sri Lanka. The installed production capacity by June 2011 will be over 11,000,000m² with 10 production lines and two coil coating lines.

ALUBOND A2 - Advantages

Alubond A2 – Creating A Sustainable Future

Alubond U.S.A is a metal composite panel consisting of two layers of a metallic skin like Aluminum, Stainless Steel, Copper, Zinc, Titanium etc., sandwiching a fire rated core in a continuous co-extrusion process.

Alubond U.S.A is a registered brand of American Building Technologies located in Rockford Illinois with production bases in Europe, Middle East and India. Alubond U.S.A is committed to a sustainable future and is now available in three fire rated cores and an innovative eco friendly green core.

Alubond U.S.A has emerged as The World’s Largest ACP Brand with new expansions under progress in Russia, Saudi Arabia and Sri Lanka. The installed production capacity by June 2011 will be over 11,000,000m² with 10 production lines and two coil coating lines.